During a media event with Remington Outdoor Company in Little Rock, Arkansas, we were offered the chance to visit their Lonoke ammunition plant. Having never been inside an ammunition plant, I was super excited for the opportunity.

Sponsored by Remington Outdoor Company

The Remington Ammunition Plant is located on more than 1,200 fenced-in acres, which also includes the Remington Gun Club. This self-sustaining compound even has its own power and wastewater treatment facility, as well as a hospital.

Security is tight around the plant. Employees all wear keycards and we entered through a building with armed guards where everyone signed in. This also meant photography was limited to close shots.

To put it all into perspective, imagine this … the Lonoke ammunition plant runs 4 shifts a day, 24/7. It produces about 10 million rounds of ammunition a day, which equals around 2.6 billion rounds a year.

One of the components of ammunition is lead. And yes, they use quite a bit of it at the plant, about 44 million pounds a year. The above photo shows raw lead sitting outside the plant waiting to be processed.

Even the scrap pieces of copper looked like a work of art.

I can’t even imagine how much ammo these carts held … and they were everywhere!

This is James, he was the tour guide for my group. James is a ballistic engineer at Remington, which meant we had an even more behind-the-scenes tour. This room, which is one of many, has a tunnel with a target at the end for ballistic testing. What you can’t see is the computer system on the side that prints out all the readouts with numbers, graphs and more, which is something I can’t even come close to wrapping my brain around.

Accuracy barrels are used to ensure every ballistic test is run the same. Remington keeps barrels from just about every firearms company out there. They use them throughout the ballistic tests as needed.

In case you had any questions about it … this is a red drum. I had to take the photo, made me giggle.

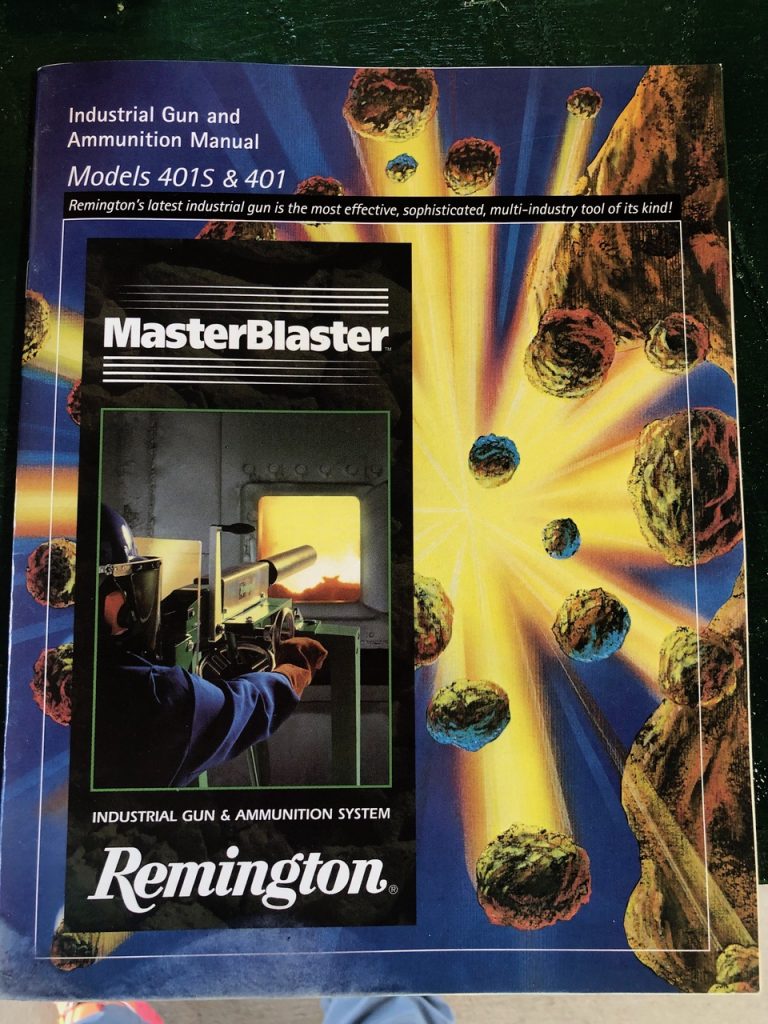

One of the cool extras of this event was when we were introduced to Remington’s MasterBlaster, an industrial gun and ammunition system.

The MasterBlaster system is a productive and cost-efficient way to remove virtually any type of build-ups in boilers, kilns, silos, quarries or mines. Although something most of us would ever need, the MasterBlaster tool is really interesting.

Before Remington developed the 8-gauge “Cement Gun” in the 1930’s, kilns had to be cleaned by teams of workers with picks and bars. In order to do this, they had to shut down the kiln and let it cool. Then, the team painstakingly pried loose the buildup of debris.

An 8-gauge industrial loaded shell is used in the MasterBlaster. It produces 9,000 pounds of energy and 150 pounds of recoil energy.

A MasterBlaster costs a mere $14,000, or you can lease one for $1,000 a month. Oh, don’t get too excited, unless you own a big giant machine that needs to be cleaned, you more than likely will never get to have a MasterBlaster.

Michelle Cerino, aka Princess Gunslinger, first entered the firearms industry in 2011 as co-owner, president and trainer at a national training company. She immediately began competing in both 3-Gun and NRA Action Pistol, becoming a sponsored shooter. Michelle is currently a columnist and Managing Editor of Women’s Outdoor News, as well as owner of Pervenio LLC. She also manages social media for Vera Koo and FASTER Saves Lives. Michelle encourages others to step out of the comforts of home and explore. View all posts by Michelle Cerino